Easier, safer and faster!

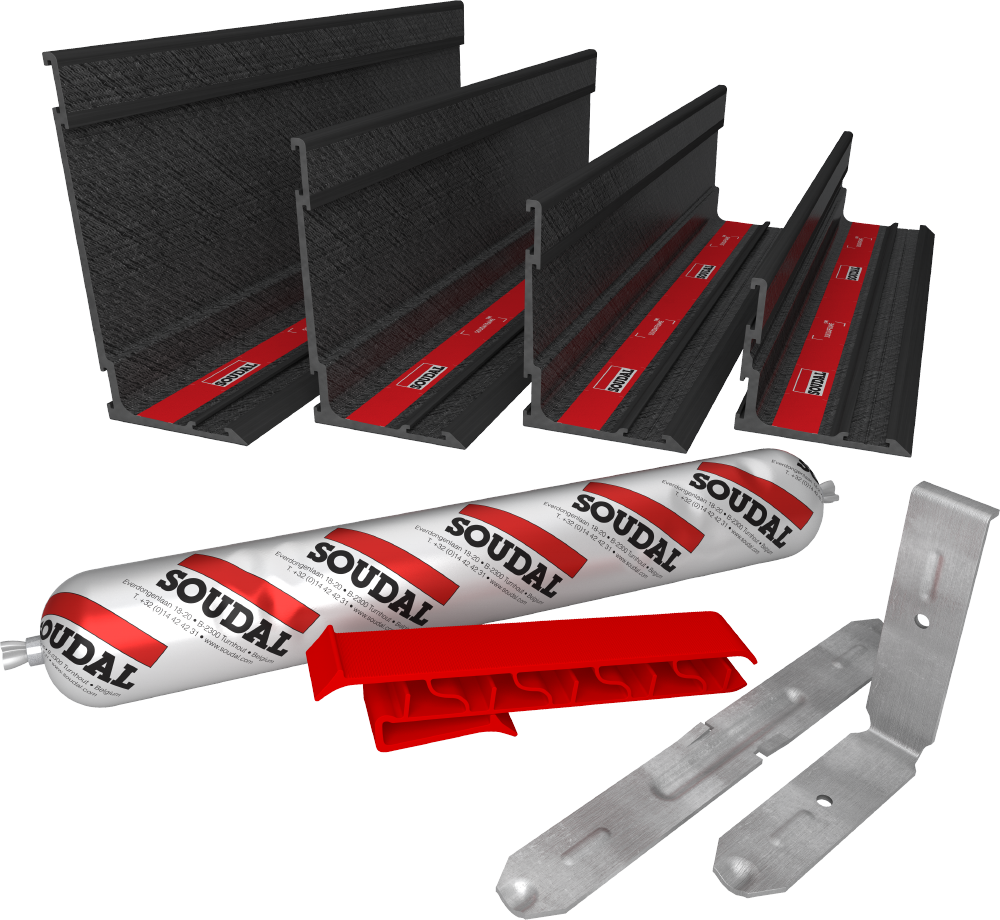

SOUDAFRAME SWI (Soudal Window Installation) is a cleverly designed pre-wall system with a very low thermal conductivity for the installation of exterior joinery, made from glass fibre reinforced plastic (GFRP). The system consists of L-shaped frame elements, which can easily be assembled to a complete pre-frame using the plug-in connection pieces. A special adhesive which bonds and seals at the same time (for an air- and watertight installation of the subframe to the wall) and spring clips for an easy adjustment and fixation of the window frame in the pre-frame.

The window frame is directly installed in the SOUDAFRAME SWI pre-frame, without the need of a metal connection between the window frame and the loadbearing wall construction. In other words a thermally optimal window installation, without thermal bridges.

SOUDAFRAME SWI creates in a single way a standardised, high quality installation, by always providing a custom-fit, dimensionally accurate, straight and square pre-frame with uniform joint dimensions, regardless of the building surface. This considerably simplifies the assembly and sealing processes, which will also result in fewer errors and a faster installation at a higher quality.

The system can be used universally for newly built and renovation for all common window profiles and materials and is available in various sizes.

Application

Today‘s requirements for energy efficient buildings require a high level of insulation. For optimum thermal performance, windows should be installed into the insulation layer. The better the insulation, the thicker the insulation layer must be, and the greater the distance between the window and the supporting wall.

For fixing windows usually metal wall brackets are used. Depending on the distance to the load-bearing inner wall, these brackets must correspondingly be heavier (and stronger). However, increasing the metal content increases the thermal conductivity, and thereby also the risk of thermal bridges and its undesired consequences (mould and moisture problems).

The very slim L-shaped frame elements enable a good connection with the insulating layer. This maximizes the surface area of the insulation layer and, as a result, improves the overall thermal performance of the building envelope.